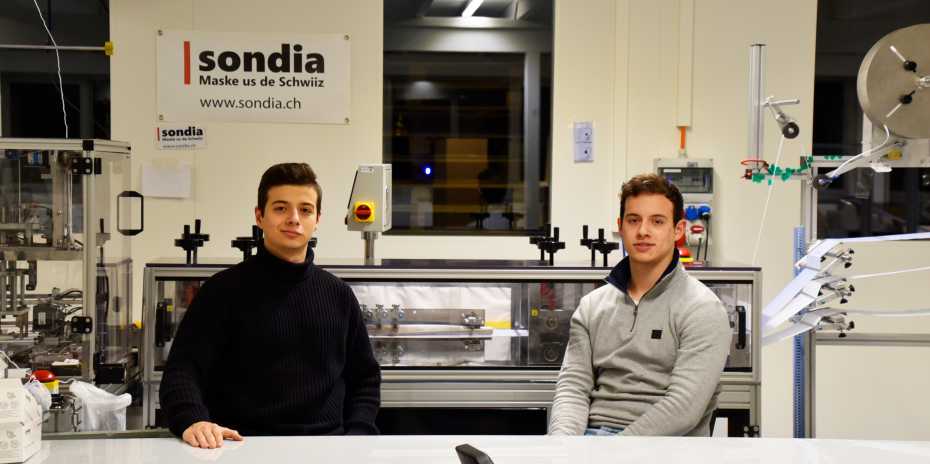

by Rafael and Gabriel Sonderegger, ETH Zurich students, 18 February 2021

In April of 2020, the first wave of the pandemic fully hit Switzerland and our lives changed drastically. As we all know, there was a severe face mask shortage caused by huge demand and limited supply, as well as worldwide export bans. That is when my brother and I decided to set up a local production in Switzerland.

Since June 2020, we operate a stable production facility for face masks locally produced in Schaffhausen. We produce about 20’000 face masks daily, which we distribute directly to companies or retail chains. Our masks can be found in pharmacies or even in bigger retailers like JUMBO all over Switzerland. But how did we get here?

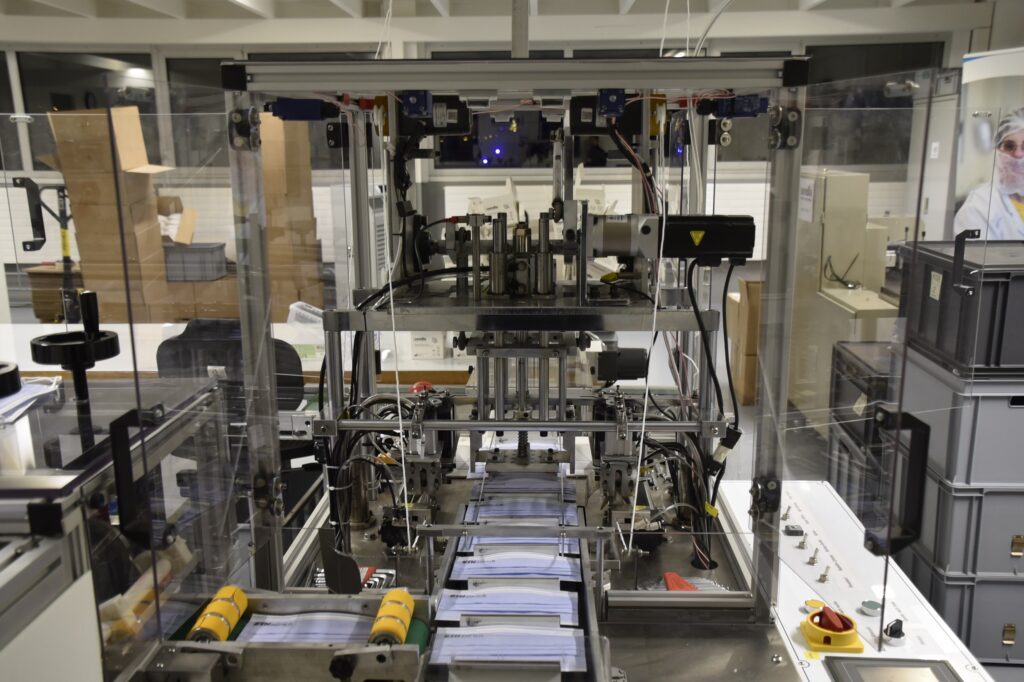

We realized the simplicity of the structure of face masks. They are made of three layers of Polypropylene, which are widely available. To create our business, we essentially needed to get three key components sorted: machinery, material, and a production site. While usually such things are planned and thought out carefully, we acted fast. We invested all our capital in machinery and material, and only then started looking for a place to set it all up. We found an industry partner in our hometown, very eager to help with our project. The company “Altra” is a large industrial employer for handicapped people. Thankfully, we found them as a partner in time, otherwise we would have ended up with tons of material in front of our house. It might seem like we took an unnecessary big risk, but at the time we were in a hurry especially due to the constantly changing political situation in Switzerland. Luckily, everything worked out in our favour.

The next big challenge which presented itself was to ensure a smooth production. While the machine in its entirety worked, we were far from a stable and safe production. First, we had to address clear security issues. As there were no covers anywhere, accidents were a possibility and had to be addressed. Further, there were a lot of technical issues which had to be solved. The first few weeks, the machine barely worked as we had hoped. But eventually, we got there. Today we produce about 20’000 masks a day.

Initially, we spent most of our time at the production site. Today, our workload has shifted to dealing with new orders, meaning our work is now done from the office. Where are we now? Since the start of our project, we manufactured over 1.5 million face masks for the Swiss market. Although there is no longer any face masks shortage to speak of, our product is still very much in demand. We know that eventually the pandemic will pass, and life will return to normal. That will probably mark the end of our project. But this experience was incredibly valuable, and we are happy to have contributed a part in the battle against Covid-19.

Link

Sondia Website (only in German): https://sondia.ch/

About the authors

Rafael Sonderegger:

The thing that keeps me the busiest at the moment is: military service

My favourite app is: Instagram

One book or movie I recommend is: Any Quentin Tarantino movie

If all else fails, my instant pick-me-up is: my dog

Gabriel Sonderegger:

The thing that keeps me the busiest at the moment is: Exams

My favourite app is: Pinterest

One book or movie I recommend is: The good, the bad and the ugly

If all else fails, my instant pick-me-up is: my phone