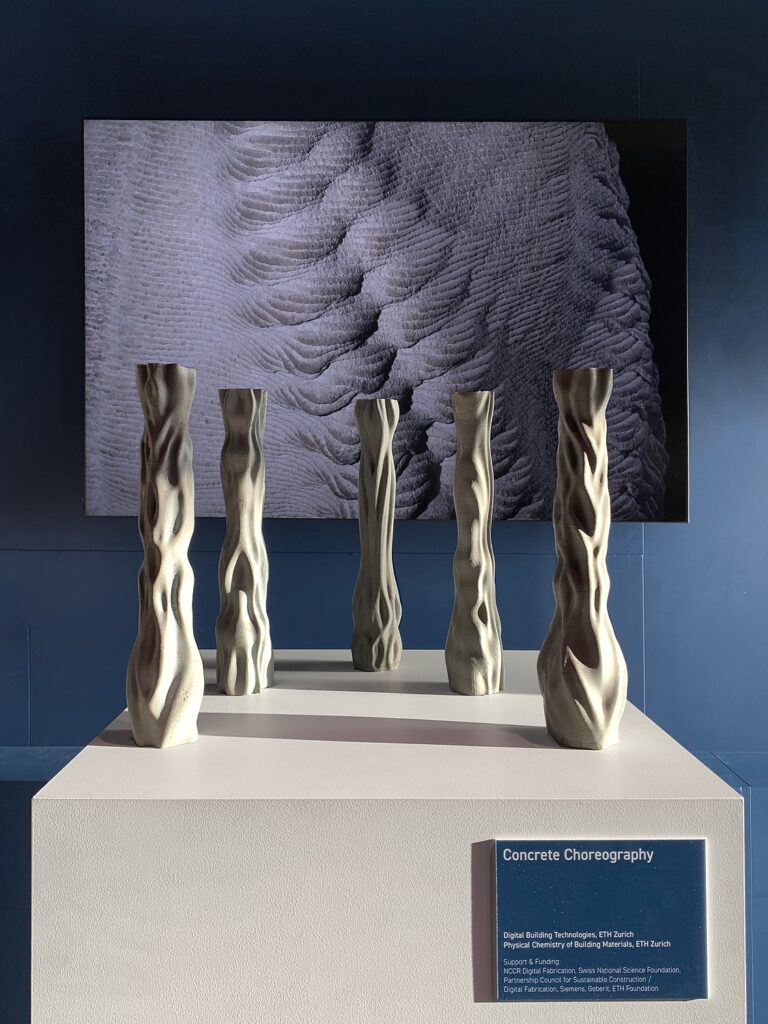

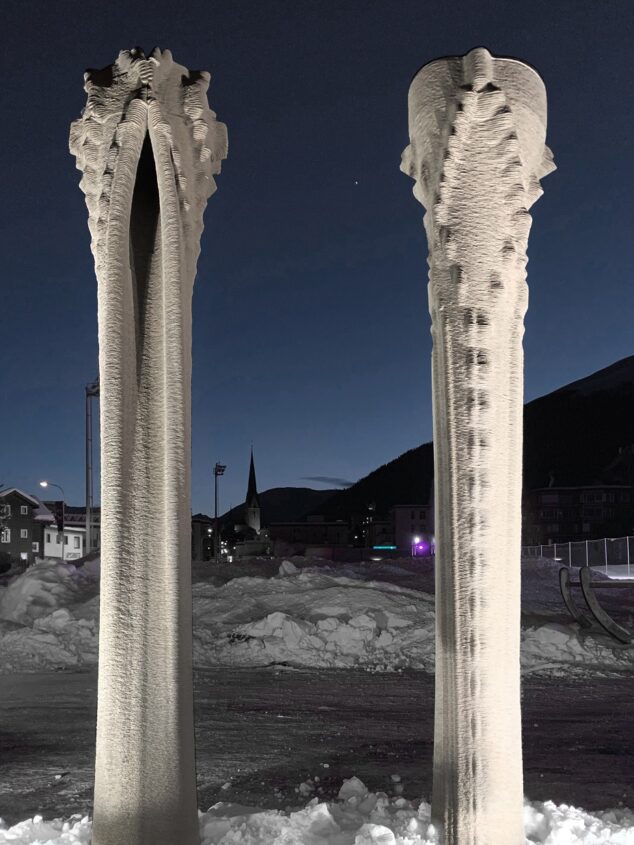

Concrete Choreography is the name given to a project exploring the 3D printing of concrete columns. It started as a design and fabrication course for the MAS of Architecture and Digital Fabrication with the aim of exploring design possibilities enabled by the novel concrete 3D printing techniques developed by Digital Building Technologies and Physical Chemistry of Building Materials teams at ETH Zurich. The first nine columns, 3D printed in the Robotic Fabrication Laboratory of ETH Zurich, were shipped to Riom in the canton of Graubünden in Switzerland to create an open-air stage for the Origen Festival of Culture. What sets this apart from the regular practice of stage design is precisely the permanence and durability of concrete. The decision to work with a structural building material emphasized how fast and easily concrete can be shaped, compared to the regular foam or glass-fibre. The larger context of the performing arts exposed the general public to new ways of designing and building with concrete. In this way, perhaps the social impact of digitization is equally relevant in shaping a digital building culture as the exact sciences are.

Shaping a digital building culture for concrete 3D printing

by Ana Anton, 11 February 2020

3D printing process ongoing interdisciplinary research at ETH Zurich (Image: ETH Zurich/Keerthana Udaykumar)

3D printing with concrete is an additive manufacturing method for large-scale architectural applications. By successively adding layers of freshly extruded concrete, the method is able to replicate digitally generated 3D models. This allows complex designs to be materialized far more quickly than using traditional methods, because computers and robots handle much of the complexity and form variation. In addition, this fabrication method can introduce a more ecological way of building with concrete. Placing material only where it is functionally required means that the pillars can be hollow, so they use less material than traditional casting methods. They also do not require any formwork during the construction process.

Further research into design, material and reinforcement have allowed the printing process to become more robust and precise, enabling taller and more slender columns. This was the starting point of showing Concrete Choreography as part of Rethink Creativity ETH Zurich Pavilion at the World Economic Forum 2020. For this occasion, two new columns were fabricated and shipped to Davos. This was complemented by a new type of interaction which we introduced to engage with the public: visitors were invited to design their own column, on a custom-developed software.

Reinventing concrete for digital fabrication processes challenges us to re-evaluate the use of mate-rials and the importance of design for more sustainable constructions. Promoting a design-oriented approach can yield spectacular results that challenge building conventions. We believe this approach is necessary to accomplish the full social, ecological and aesthetic potential of con-crete in a digitized building industry.

About the author

Ana Anton is a doctoral candidate in the chair for Digital Building Technologies at ETH Zurich and associated to the National Center for Competence in Research - Digital Fabrication, where she leads the research in concrete 3D printing.