Achieving ultra-high precision and quality in machine manufacturing processes sometimes depends on small but important details. As any sushi eater knows, you only need a small amount of wasabi to make a huge difference!

Sushi and Ultra-high Precision Manufacturing

by Caroline Nadiaska Mayer, 26.09.2019

Fushiri Inari Shryne, Kyoto (photo credit: Philipp Mayer)

Ohori Grinding Company

Titanium components of a satellite for Saturn’s orbit, Inconel Formula 1 engine shafts, mechanisms for airplane flaps, Carbon Fiber Reinforced Polymer Composites (CFRP) for wrist and clavicle implants, aluminum air bearings… These are just some of the breath-taking technologies processed under the roof of the Ohori Grinding Company in Japan.

Titanium components of a satellite for Saturn’s orbit, Inconel Formula 1 engine shafts, mechanisms for airplane flaps, Carbon Fiber Reinforced Polymer Composites (CFRP) for wrist and clavicle implants, aluminum air bearings… These are just some of the breath-taking technologies processed under the roof of the Ohori Grinding Company in Japan.

I had the opportunity of completing an internship there as through the Greater Nagoya Initiative and ETH Zurich, which is the Leading House for the Bilateral Science and Technology Cooperation Programme of Switzerland with China, Japan, South Korea, and the ASEAN region.

Working with Ohori Grinding Company team was a very constructive and enjoyable opportunity (photo credit: Takashi Fujita)

Breathtaking technologies at the Ohori Grinding Company

"Only accept challenges that other manufacturers cannot in prototyping, manufacturing, or consulting services"Ohori Grinding Company’s philosophy to acquire customers who require special treatment during the manufacturing process of their products’ components.

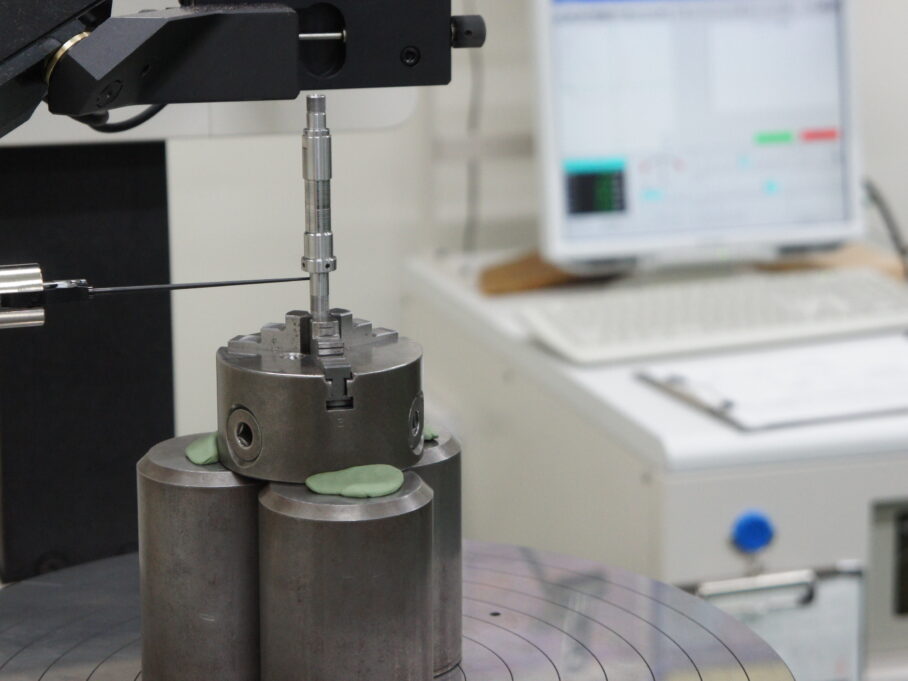

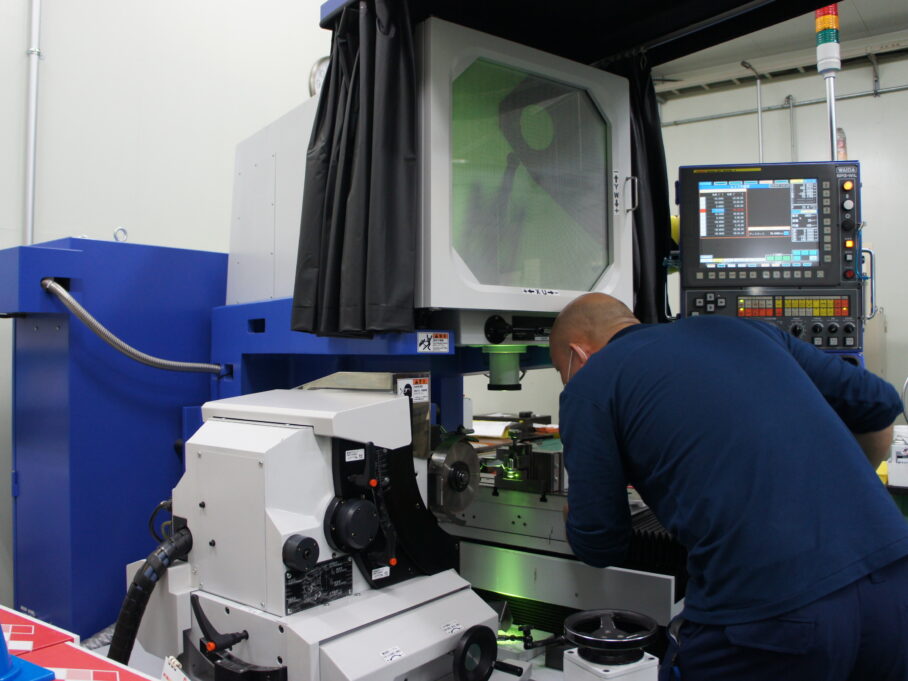

Micro-scale Precision Manufacturing

As the taste of sushi changes drastically according to who prepares it, anything manufactured at a micro-scale precision is the realm of a skilled technician. Even with the most sophisticated equipment, Ohori Grinding Company strives for perfection through the skills of their experts and delicate attention to detail that only years of experience can offer. As a “chef’s secret”, the factory relies on numerous customized techniques to process a vast variety of materials, complex parts or individual customer requirements. All this is achieved thanks to the master of competencies that the company strives to keep and grow at home.

As the taste of sushi changes drastically according to who prepares it, anything manufactured at a micro-scale precision is the realm of a skilled technician. Even with the most sophisticated equipment, Ohori Grinding Company strives for perfection through the skills of their experts and delicate attention to detail that only years of experience can offer. As a “chef’s secret”, the factory relies on numerous customized techniques to process a vast variety of materials, complex parts or individual customer requirements. All this is achieved thanks to the master of competencies that the company strives to keep and grow at home.

I was astonished by the vegetable factory the company created aside to keep veteran talents, that desire to keep working, in the company while offering them appropriate job options.

I promised sushi, and this local vendor exceeded all my expectations (Caroline N. Mayer)

As an initiative to keep veteran talents who desire to keep working, the company designed alternative working strategies suitable for them in their vegetable’s factory (Caroline N. Mayer)

Japanese Hospitality

Upon my arrival in Japan, I was quickly delighted by the overwhelming hospitality that every manager, coworker and even their families showed to me during my entire stay. Unconsciously, I easily forgot about any language barrier or cultural differences, and I became totally absorbed in the process of exploring my new setting. This ranged from techniques used by each department to process all kinds of technologies, to the explosive culinary and historical wonders that Japan has to offer. However, nothing would have had as much an effect on me as it did without the kindness, help, and support that everyone in the company offered me. Although there were times that my intuitive abilities were challenged to their maximum, in general, I was amazed by how I came to understand others, without actually understanding them.

Upon my arrival in Japan, I was quickly delighted by the overwhelming hospitality that every manager, coworker and even their families showed to me during my entire stay. Unconsciously, I easily forgot about any language barrier or cultural differences, and I became totally absorbed in the process of exploring my new setting. This ranged from techniques used by each department to process all kinds of technologies, to the explosive culinary and historical wonders that Japan has to offer. However, nothing would have had as much an effect on me as it did without the kindness, help, and support that everyone in the company offered me. Although there were times that my intuitive abilities were challenged to their maximum, in general, I was amazed by how I came to understand others, without actually understanding them.

Kakamigahara City- Center of the Japanese Aerospace Industry

Personally, I particularly enjoyed the strategic position that the company is located in. Kakamigahara city is the center of the Japanese aerospace industry and recognized as a “park city” with an infinite number of green spaces on offer. Every sunset, Kakamigahara’s sky stages a display full of Japanese military airplanes being tested, transporting me to a national independence day parade every day. However, the best of this central location is the convenient connections to any major Japanese city by a couple of hours with the Shinkansen bullet train. I could easily connect to Tokyo, Kyoto, Osaka, Nara, Hiroshima, Hakone, and other local towns, enabling me to enjoy to a maximum my time in Japan.

Gundam Unicorn, Odaiba, Tokyo (photo credit: Philipp Mayer)

Japanese Culture Introduction Days

I also experienced “Japanese culture introduction days” when the staff of the company introduced me to different world heritage sites while trying all types of activities. We made our own paper and bamboo fans at Mino city, visited the most famous samurai Castle in Gifu, tried a tea ceremony in Inuyama city, explored the traditional town of Shirakawago, ate Hida beef at Takayama, experienced a summer fireworks festival at Gifu city, visited the Kakamigahara’s air and space museum, and were amazed by the countless impressive historical wonders of Kyoto. Wonderful experiences that will remain clearly in my mind and hopefully someday I can revive again.

I also experienced “Japanese culture introduction days” when the staff of the company introduced me to different world heritage sites while trying all types of activities. We made our own paper and bamboo fans at Mino city, visited the most famous samurai Castle in Gifu, tried a tea ceremony in Inuyama city, explored the traditional town of Shirakawago, ate Hida beef at Takayama, experienced a summer fireworks festival at Gifu city, visited the Kakamigahara’s air and space museum, and were amazed by the countless impressive historical wonders of Kyoto. Wonderful experiences that will remain clearly in my mind and hopefully someday I can revive again.

About the author

Caroline Nadiaska Mayer is a Mechanical Engineer from Korea University, majored in Mathematics at The Colombian School of Engineering and pursuing ME. Business Engineering and Production at ZHAW. Caroline is currently working at the ZHAW Institute of Development in the Transition of regional energy systems team.

ETH Zurich is the Leading House for the Bilateral Science and Technology Cooperation Programme of Switzerland with China , Japan, South Korea and the ASEAN region. In this function, ETH Zurich offers a wide variety of funding instruments to enhance the scientific cooperation with Asian countries.